Effortless JPEG Compression Straight from Your Industrial Cameras

If you're a system, software, or automation engineer, you’re already dealing with the pitfalls of JPEG compression: altered image quality, inconsistent color accuracy, visual artifacts, and a loss of critical detail. While it reduces storage costs, it shifts the challenge to CPU processing. The real challenge lies in making the most of JPEG compression while minimizing its impact. Discover how to optimize this common solution without compromising performance.

Data transmission, processing and storage bottlenecks

On factory floors, the machine vision system needs to inspect multiple product lines at different facilities and transfer data to central server for quality monitoring. And in many industries, the images of critical parts need to be archived during each manufacturing stage to keep traceability. Imagine these are required in a real-time processing environment, with multicamera setup. The sheer volume of image data produced by the cameras can quickly overwhelm the system network bandwidth during transmission and puts the limits of storage space and efficiency to test.

Many JPEG compression solutions often incur high costs

JPEG compression is a widely used in machine vision when storage and transmission efficiency are application priorities. However, it can significantly strain system performance due to its computational complexity, especially in real-time environments. While it reduces storage costs, it shifts the challenge to CPU processing. The trade-off between reduced file sizes and processing speed becomes a limitation, particularly in high-speed, high-resolution systems.

Commonly used approaches and their limitations

Current solution | How it works | What are the limitations |

Post-Processing | You compress on another computer after the image capture is complete. | High CPU Network bandwidth issues High processing delays |

|---|---|---|

External Frame Grabbers | You use a standalone device compressor between your camera and the system. | Additional spending on hardware Setup can get complex with multiple cables and connections Frequent failures |

Reduced Resolution Capture | You capture images at lower quality or reduce the region of capture. | Loss in image details Cannot accommodate change in your needs Limited application scope |

Basler's seamless compression without compromise

With Basler, you can finally say no to bandwidth bottlenecks, compromise on image quality or performance, or break the bank on storage.

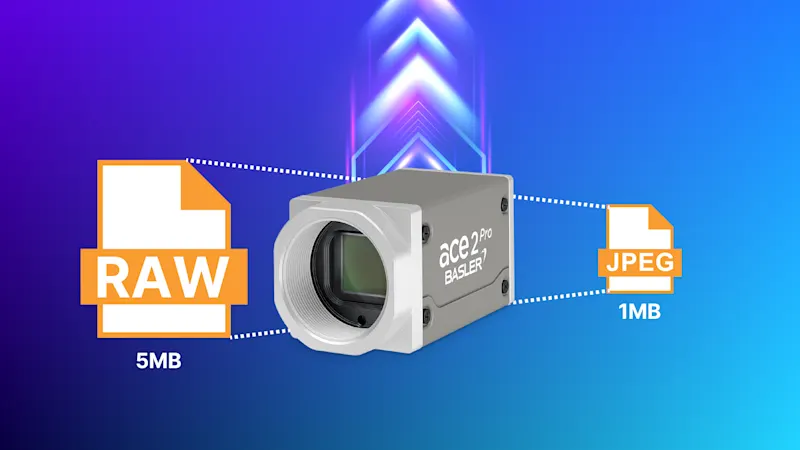

Basler's on-camera JPEG compression

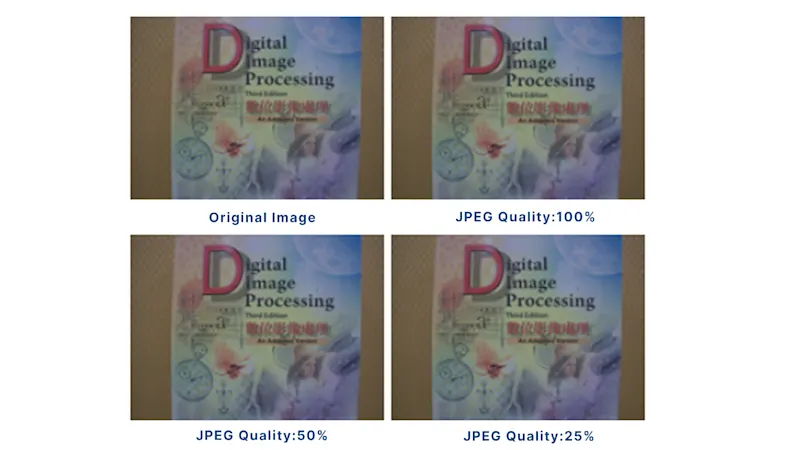

We integrate our JPEG compression algorithm directly into our industrial camera’s hardware, bringing together the strengths of industrial and network cameras. This arrangement can process raw images immediately upon capture. The in-camera approach eliminates backend bandwidth bottlenecks without having to compromise on the image quality.

High image fidelity and performance make this ideal for a wide range of machine vision applications.

JPEG compression solution highlights

By using Basler’s machine-vision-ready solution, you’re getting:

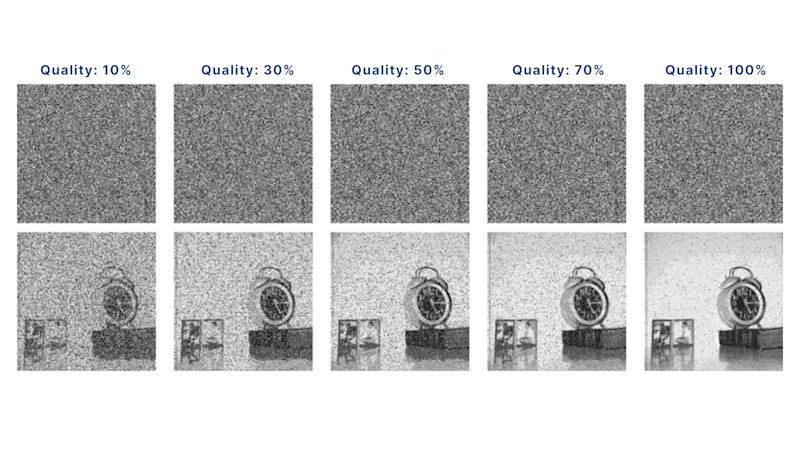

80% compression rate but without compromising on critical image details for machine vision applications

5X bandwidth efficiency across your existing architecture without having to invest in additional hardware, setup, or storage

Real-time processing at full frame rates for highly optimal performance so you can scale seamlessly

Feel free to discuss your project with our engineers so we can help you find the right industrial camera to meet and go beyond your needs.

Products for this solution

Looking to implement a comparable solution? These products will help you.