Efficient Optical Character Recognition (OCR) on Chip and IC Trays

Discover our easy and efficient way of implementing OCR solution for chip and IC trays, where challenging characters are deciphered correctly every time. The solution overcomes low contrast and variable working distances in fast-paced production environment.

Why do chip trays need OCR?

In semiconductor manufacturing, accurate identification and traceability of chip trays and IC trays is crucial for quality control and inventory management over the manufacturing process. Trays and individual chips are marked with unique identifiers that need to be reliably read in challenging conditions, such as poor lighting, inconsistent markings, variable working distances, and high throughput requirements. Accurate chip trays OCR prevents mix-ups, ensures traceability, and maintains production integrity, avoiding downtime, recalls, and regulatory issues.

The key challenges in OCR for chip and IC trays

OCR for chip and IC trays face several technical challenges due to variable readout conditions. Characters are often marked on tray edges with minimal contrast against the background, leading to poor grey-level differentiation. Additionally, variations in height of raised characters plus small font sizes further complicates readability, particularly in fast-paced production environments. These factors make it difficult for traditional OCR systems to deliver consistent and accurate performance.

Unlocking OCR success: from chip trays to complex applications

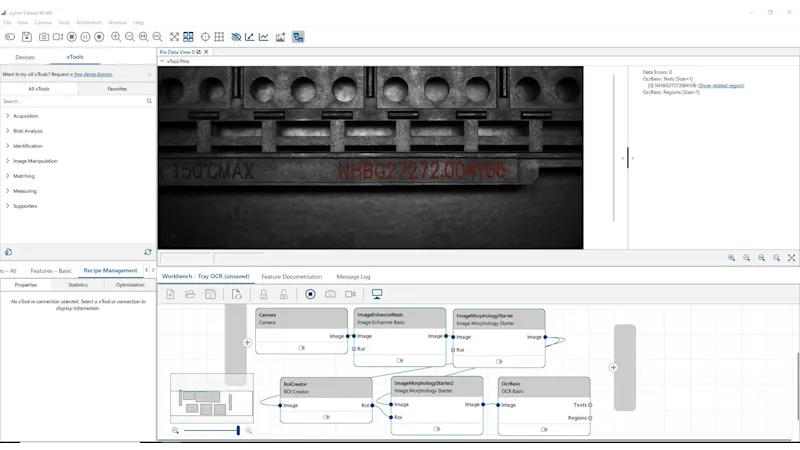

To achieve reliable OCR results on chip trays and IC trays, starting with a well-focused, high-contrast image is essential for robust character recognition. The low contrast of raised characters on chip trays can be effectively managed with professional lighting setups, while Basler’s in-camera autofocus solution ensures seamless handling of variable working distances for consistently sharp images.

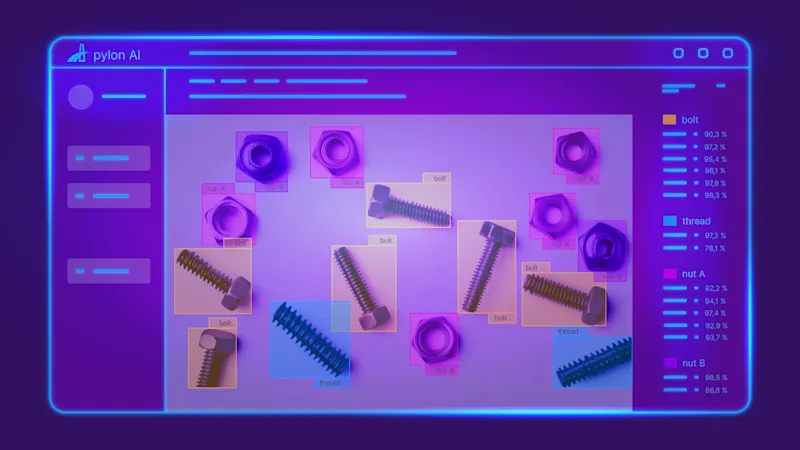

On the software side, the pylon vTool OCR accurately reads text with minimal setup required, making it highly effective and easy to integrate. For more complex OCR applications beyond chip trays--such as those involving variable positioning, distorted characters, or cluttered backgrounds--our AI-based OCR solution excels at tackling these challenges, ensuring reliable performance in any environment.

Get expert help for your OCR project today!

OCR solution benefits

Reliability: consistent, accurate OCR results ensure dependable performance.

Need-Specific: our OCR solutions aim to meet your specific need--with smart lighting, or autofocus, and cost-effective pylon vTool OCR software.

Ease of deployment: quick field deployment without the need for programming expertise or extensive vision knowledge.

For smaller vision teams or those with limited OCR expertise, our solution offers exceptional value. It simplifies deployment and integration, providing a cost-effective option that requires minimal resources and technical know-how.

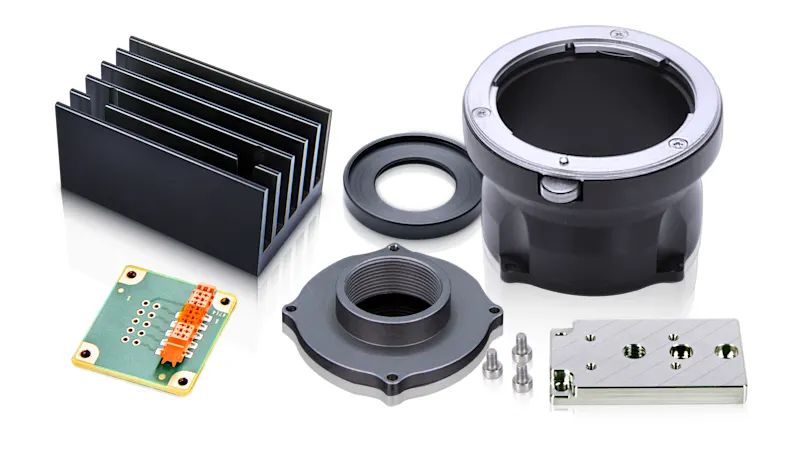

Start your free consultation now!Products for this solution

Looking to implement a comparable solution? These products will help you.