Traitement d’images dans la fabrication de cellules de batterie

La vision industrielle permet le contrôle de la qualité

Dans la production de cellules de batterie, il est essentiel de garantir une qualité élevée à toutes les étapes du processus et de réduire les déchets de matériaux. Le traitement d’image numérique permet de détecter de manière fiable les plus petits défauts. Nos solutions permettent de produire des cellules de batterie sûres et de haute qualité pour répondre aux défis de la mobilité électrique.

Hautes performances et vitesse

Une technologie de caméra innovante et performante pour des méthodes de production de pointeDurable et fiable

Avec le taux de défaillance le plus bas de l’industrie, nos systèmes de caméras sont synonymes de fiabilité en fonctionnement 24h/24 et 7j/7Une intégration simple

Tous nos composants sont compatibles et faciles à connecter aux systèmes cibles à l’aide du logiciel pylonDisponibilité et livraison fiable

Des chaînes d’approvisionnement stables garantissent la disponibilité à long terme de nos produits et évitent les temps d’arrêt de la production

Contrôle qualité efficace dans la production de cellules de batterie

Découvrez dans notre webinaire :

Comment la vision industrielle est-elle utilisée pour lecontrôle qualité dans la production de cellules de batterie

En savoir plus les applications typiques de vision industrielle dans la production de cellules de batterie

Comment vous pouvez augmenter l' efficacité de votre production en utilisant la vision industrielle

Différents types de cellules

La principale application des batteries lithium-ion est la mobilité électrique. Bien qu’il existe trois types et formats utilisés, le principe de fonctionnement de tous les types est essentiellement le même. Les principales différences résident dans la conception, les exigences et les matériaux utilisés.

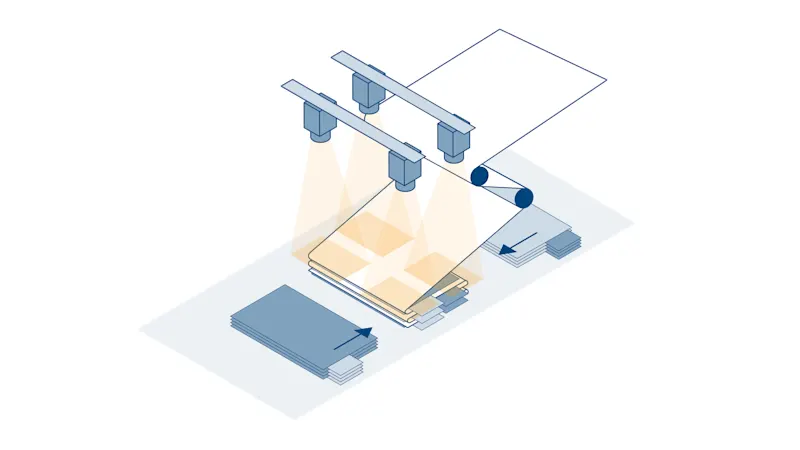

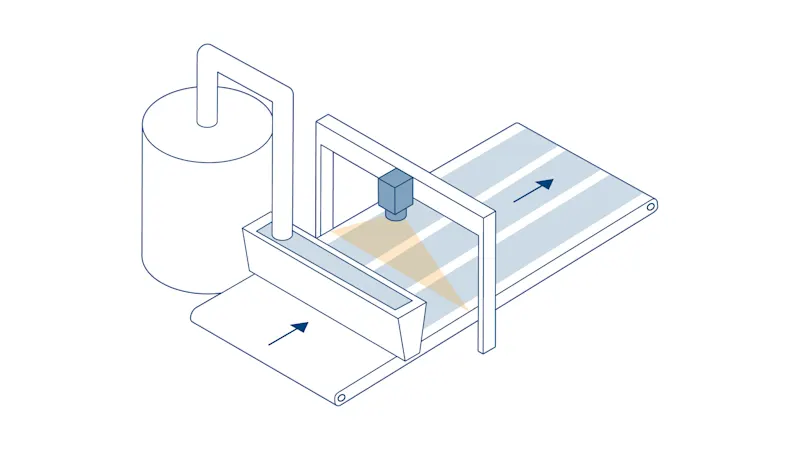

La fabrication des cellules de batterie comporte quatre étapes principales

La production de cellules de batterie lithium-ion se compose de quatre étapes de processus principales : production d’électrodes, assemblage de cellules, finition de celluleset assemblage du bloc-batterie. Les étapes du processus de production et de finition des électrodes sont largement indépendantes du type de cellule de batterie, tandis que l’assemblage des cellules fait la distinction entre les cellules à poche ou prismatiques et les cellules cylindriques. Quel que soit le type de cellule, la plus petite unité d’une cellule lithium-ion se compose de deux électrodes et d’un séparateur qui les sépare l’une de l’autre. Entre les deux se trouve l’électrolyte conducteur d’ions.

La vision industrielle garantit la qualité du produit et la stabilité du processus

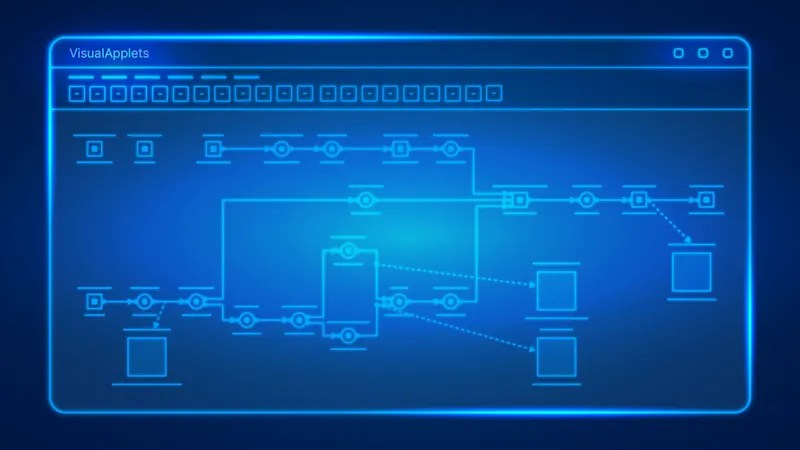

Les systèmes de vision industrielle fournissent des informations précieuses pendant le processus de production, notamment l’inspection des matériaux et la vérification de la bonne exécution des étapes du processus. Différentes solutions sont disponibles en fonction des besoins de votre application. En combinant nos systèmes basés sur la carte d’acquisition d’images

VisualApplets et nos caméras linéaires haute sensibilité , le système de vision qui en résulte peut facilement s’adapter aux vitesses élevées que l’on trouve dans la production d’électrodes. Les caméras haute résolution ace 2 X visSWIR inspectent les structures des feuilles de séparation à l’intérieur de la cellule. Nos caméras matricielles en collaboration avec pylon vTools, vérifient que la cathode et l’anode sont correctement positionnées l’une sur l’autre lors de l’enroulement des cellules prismatiques. Il est essentiel de détecter le moindre défaut, car un suivi précis des erreurs augmente la productivité.

Où la vision est-elle utilisée dans la fabrication de cellules de batterie ?

Cas d’utilisation dans la fabrication de cellules de batterie

La vision industrielle permet de garantir la qualité des matériaux traités et de minimiser les éventuels déchets de matériaux. Nos solutions peuvent vous aider.

Produits les plus populaires

Pour des applications de vision industrielle efficaces et fiables dans ce secteur, les produits Basler suivants sont souvent le meilleur choix :