Automated Optical Inspection (AOI)

Optical measuring systems inspect objects and detect a wide variety of features. With its large selection of area scan and line scan cameras, Basler offers the right model for every camera inspection task.

L’importance de l’inspection optique dans le traitement d’images industrielles

L’inspection optique joue un rôle dans les différents domaines d’application de la vision industrielle industrielle. Quels que soient leur domaine d’utilisation spécifique et leurs exigences, toutes les caméras de vision industrielle ont une mission commune : l’inspection optique. Cela signifie trouver et identifier des caractéristiques qui servent de base aux analyses et produisent des conclusions qui peuvent être utilisées pour le traitement continu.

Complex inspection tasks for measurement and error detection

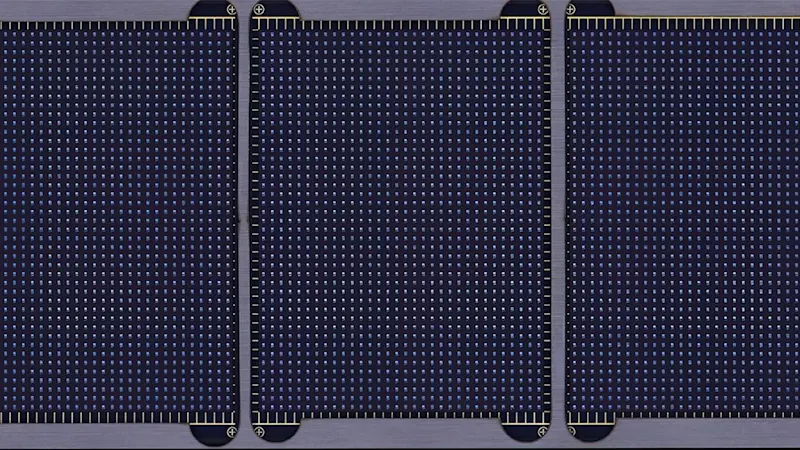

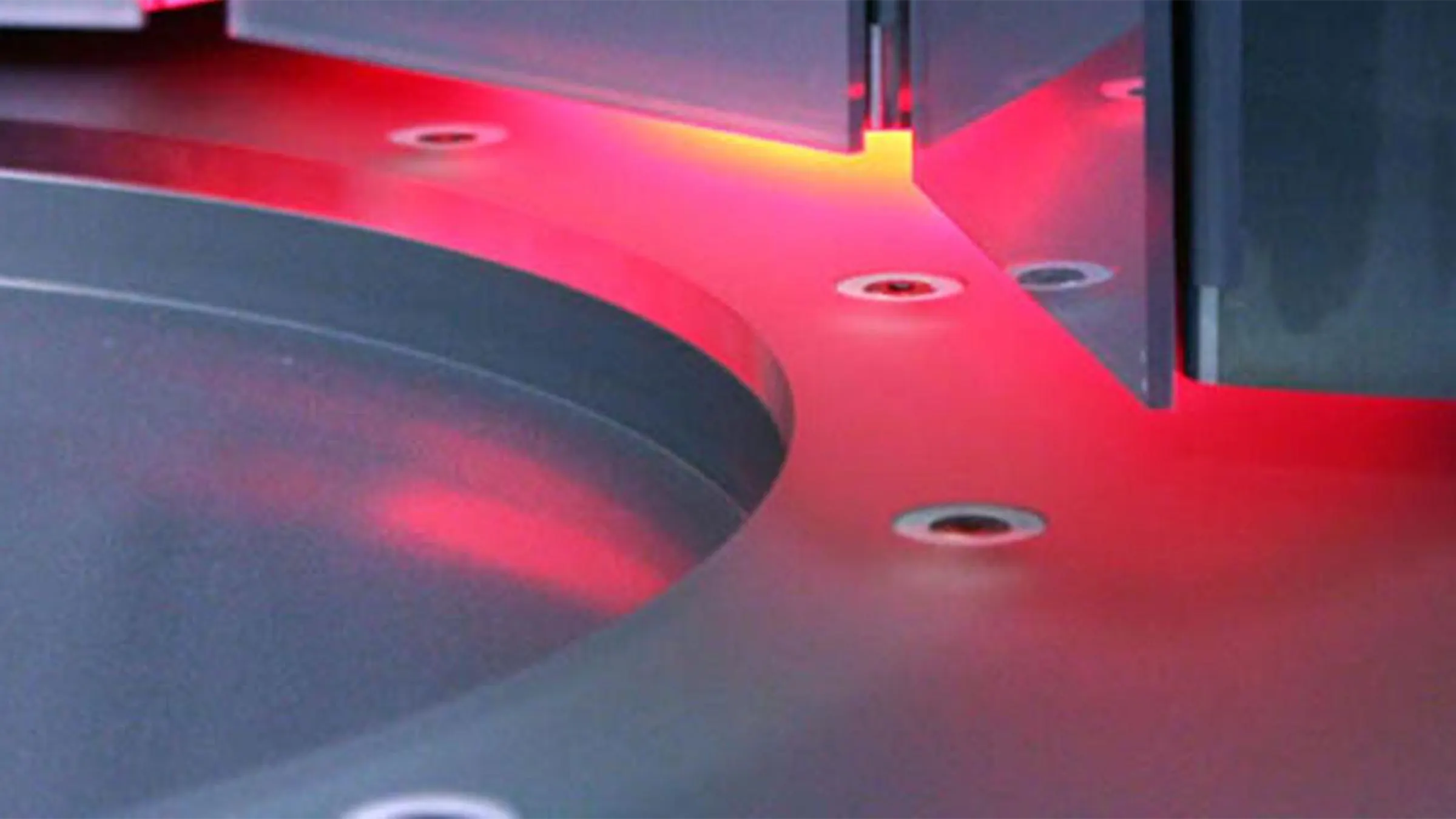

Based on the identified characteristics, AOI systems can undertake optical measurements as dictated by the problem at hand and identify any deviations from the standards. Industrial machine vision is perpetually focused on so-called grayscale value deviation. The grayscale value indicates the brightness of a pixel, independent of color. Depending on how this grayscale deviation is configured, it is possible to

sort objects (foods, merchandise)

detect errors (scratches, entrapment)

measure sizes (packets, O rings)

inspect surfaces (films, glass) or

inspect circuit boards (for correct position of the solder points)

Exemples d’application de l’inspection optique automatique (AOI)

En savoir plus sur nos produits et leurs applications. Notre matériel d’information complet vous fournit tous les détails importants.

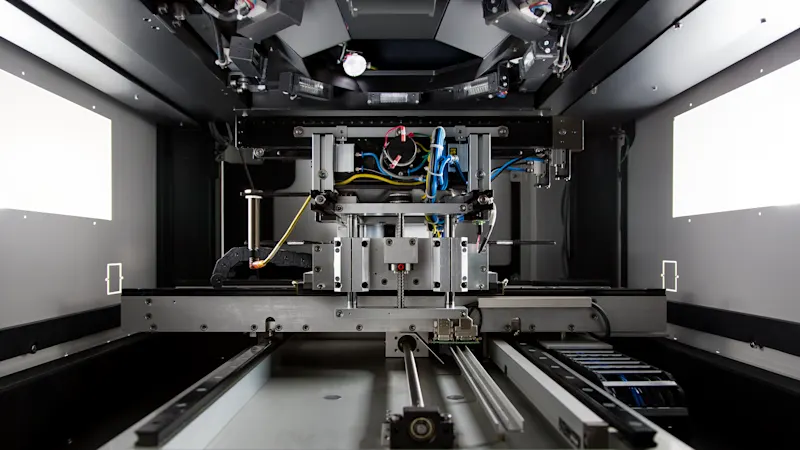

Individual opportunities – flexible use

Automated optical inspection can be established at various spots in the production process to fit specific needs: Directly within production or as part of packaging, with 100% control or via trial-and-error testing. The use of powerful cameras with high frame rates allows for inspections to be run without disrupting the production workflow.

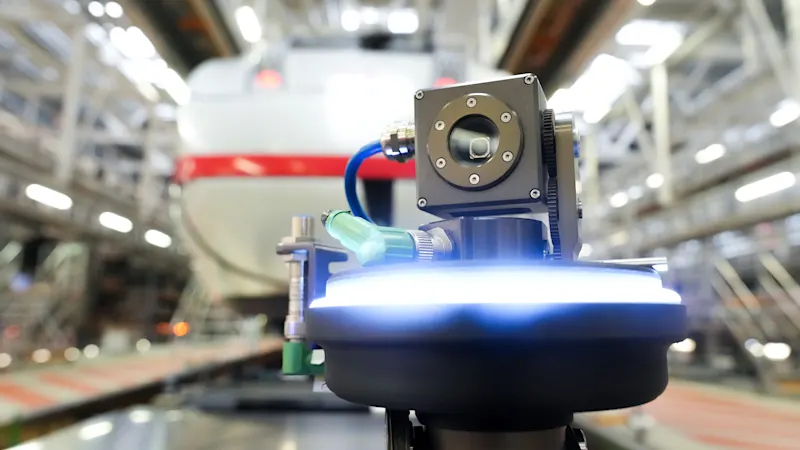

Composants nécessaires

La configuration des systèmes d'inspection optique comporte de nombreuses facettes. La caméra de vision industrielle n'est qu'un élément parmi d'autres. Un éclairage adéquat - artificiel ou naturel - ainsi qu'un déclencheur, c'est-à-dire un signal sous la forme d'une barrière lumineuse ou d'un encodeur qui déclenche essentiellement la caméra, sont d'autres éléments matériels indispensables.

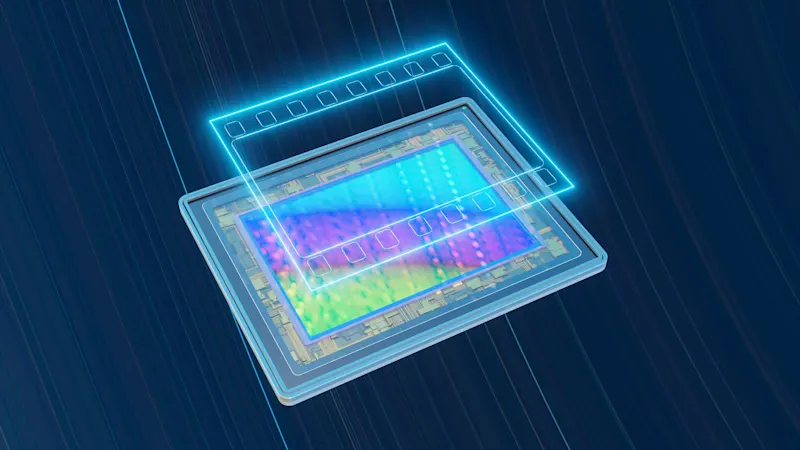

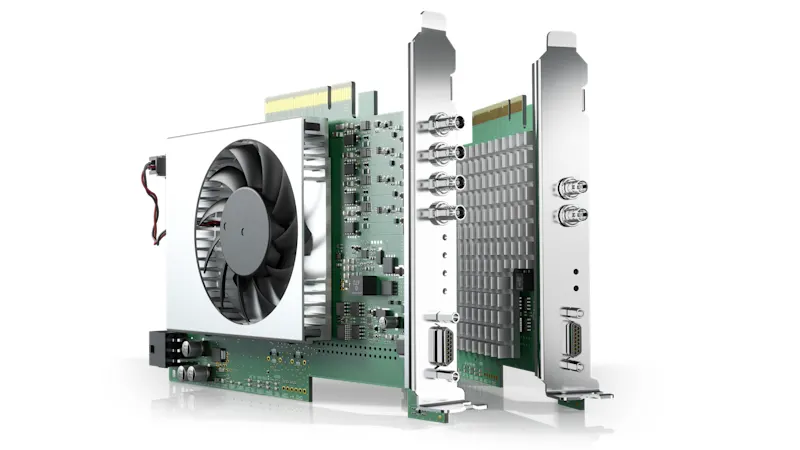

Le prétraitement de l'image, tel que la détection du code, s'exécute sur le FPGA de la plateforme VisualApplets (par exemple, dans la carte d'acquisition d'images ou sur la caméra). Au cours de ce processus, une région d'intérêt est définie de sorte que seules les zones d'image pertinentes sont transmises. Cela permet de réduire le volume de données et le temps de transmission. Les données d'image prétraitées sont ensuite transférées via l'interface de la caméra à l'unité informatique, où elles sont traitées et évaluées par le logiciel d'analyse.

Logiciel d'analyse d'images pour l'inspection optique automatisée

Pour l'inspection optique automatisée (AOI), nos logiciels complémentaires, les pylon vTools, offrent une vaste sélection de modules puissants.

Un choix robuste et précis est celui des algorithmes d'IA En particulier, Détection d’anomalies et les deux vTools de segmentation (Segmentation des instances & Segmentation sémantique) sont optimales pour la détection des défauts et l'analyse des écarts dans le cadre de l'assurance qualité.

En outre, les Code Reader vTools tels que QR Code Reader Pro, Lecteur de codes-barres ou Lecteur de code Datamatrix sont adaptés à un suivi rapide et fiable des produits.

Pour les tâches AOI classiques, des outils tels que Correspondance des modèles, Correspondance de motifs géométriques et Analyse des blocs de couleur sont disponibles - ils permettent une détection robuste des défauts, l'identification des objets et des formes, ainsi que des processus de tri et d'inspection. Les vTool Measurements fournit des mesures précises des distances et des dimensions pour l'assurance qualité.

Vers pylon vTools