Light in Machine Vision

How to find the right lighting

Vision system lighting is often neglected in planning, but it is crucial for image quality and efficiency. Without the right light source, reflections and dark or overexposed areas will occur. Therefore, pay close attention to lighting technology that suits both the intended use and the overall system. Find out which lighting is suitable for your system and what you should consider when making your choice.

Lighting types in machine vision

Choosing the right lighting is critical to the effectiveness of an inspection task. For example, different lights are used to detect cracks verses distinguishing colors. LED lights are the most commonly used for machine vision because they are cheaper and more efficient than, for example, halogen lamps or fluorescent tubes.

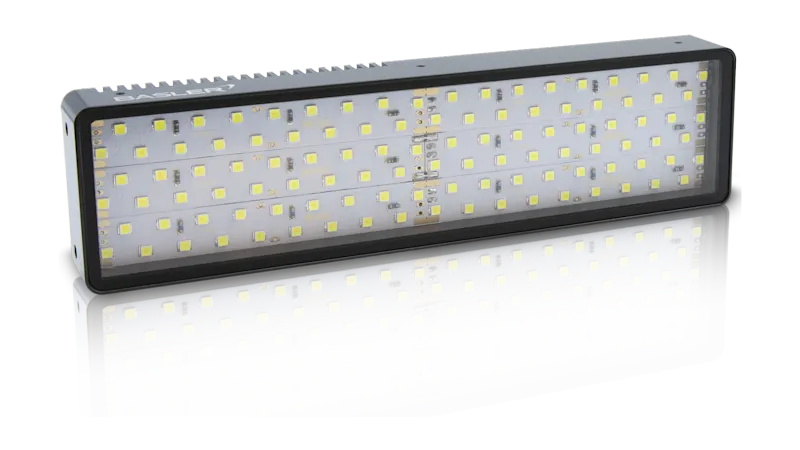

Bar lights

The light comes from a straight bar to evenly illuminate the surface. It is also possible to combine several bar lights so that the motive resp. object is illuminated from different sides. Bar lights can be used to specifically illuminate certain parts of an object, which is necessary in some applications. They are often used in combination with darkfield illumination, which makes it very easy to inspect surfaces for scratches and abnormalities.

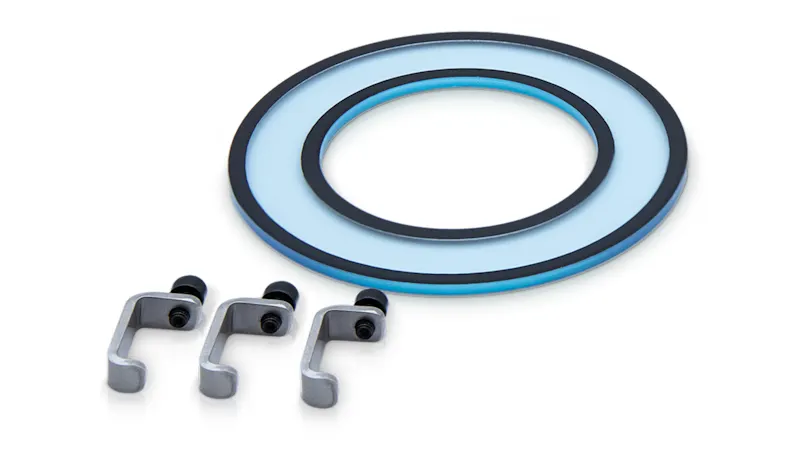

Ring light

Ring lighting is circular, illuminating the object evenly without casting a shadow. Ring lights are a typical form of front light lighting, which increases the contrast in images due to the illumination. The lights are easily adaptable and could be described as "all-rounders" in lighting technology. Ring lights are particularly popular for quality control work with cylindrical objects, as they illuminate them evenly from the outside due to their round shape.

Back light

In this lighting technique, the object is evenly illuminated from behind so that the outlines are well defined or the object is screened. For example, holes, bubbles, or scratches can be noticed and displayed very clearly. Back light is also an important standard in the quality control of labels and printed paper. However, all information regarding the surface texture is lost.

Influence of angles of incidence on lighting

The angle of incidence of the illumination on the object plays an important role in image processing. Depending on the angle of incidence, different features of an object are displayed or hidden.

Detect scratches

If you would like to use a vision system to identify scratches, then it's recommended to use light from the side. The scratch then reflects the incoming rays of light in the direction of the camera, making it appear bright.

Hide scratches

If you would like to hide scratches, illuminate the object from many different angles (such as from above with a ring light). This means that there are no shadows, allowing other features such as color or print to be recognizable without interference.

Light in machine vision: colored light and wavelengths

In image processing, you can make use of other light properties. Different wavelengths of light hitting different materials will cause the light to be refracted, absorbed, conducted, or reflected. In the case of vision systems and their lighting technology, the absorption and reflection of light is particularly interesting.

Color in quality assurance

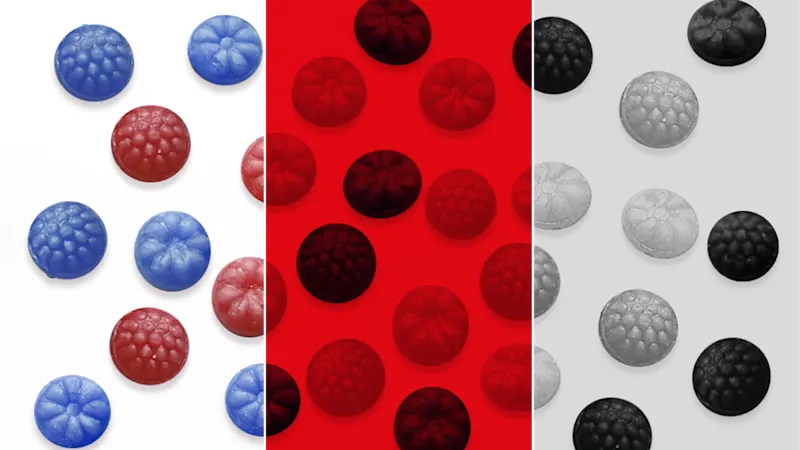

Whether an object reflects, refracts, or absorbs light depends on its physical properties. Mirrors reflect light, water and air refract it, and absorbent materials convert it into heat (such as heated surfaces in the summer). Objects reflect the color they themselves have: a red object reflects red light, a blue one absorbs it.

These conditions can be used in quality assurance: with a monochrome camera and red light, red objects appear bright, while blue objects appear dark. Monochrome light sources also often provide a sharper image, as chromatic effects of the lens are excluded.

Invisible wavelengths

Light is visible to the human eye in the 400 to 700 nanometer range because it takes on different colors in this spectrum. Light beyond this visible spectrum can reveal features that are otherwise invisible to humans: for example, pressure marks on fruit can be detected particularly well with infrared (IR) light. SWIR cameras and special SWIR illumination are particularly well suited for this.

Coordination of your lighting technology

Lighting is only one part of the vision system. However, the choice of lighting technology is decisive for the image quality—other components cannot compensate for the quality of the light source. Therefore, when putting together your vision system, you should deal extensively with the topic of lighting.

How to choose your lighting

First, narrow down the object characteristics that you want to make visible. Various properties of the object under consideration are important: What material is it made of? Does it reflect or absorb the light? What kind of structure, geometry, and color are involved? The motion of the object, ambient light conditions, and the distance to the object also impact the choice of lighting.

Based on these factors, you can accurately determine the lighting needed. For additional support, our Illumination Advisor gives you individual product recommendations. It guides you step-by-step to a selection of coordinated lighting.

Our lighting products

Choose the right product for your vision system from our broad portfolio.