What is Machine Vision?

Industrial image processing, often referred to as machine vision, has become an indispensable part of automation and quality assurance. With the use of state-of-the-art camera systems, processes can be optimized, quality increased, and production costs reduced in the long term.

Precision and efficiency through machine vision technology

Machine vision is an area of industrial automation that deals with the acquisition and analysis of images to control, regulate, and monitor automated processes. This technology uses digital cameras, image processing software, and optical systems to capture images of objects and analyze their features.

How vision systems work

A machine vision system typically contains several components that work together. For example, a machine vision camera captures an image of a product on a conveyor belt. These images are then processed using specialized image processing software, such as the Basler pylon Software Suite. Within this software, algorithms are used to detect and check certain properties such as size, shape, color, or surface finish.

The results of these tests can then be used to perform quality controls, control manufacturing steps, sort parts, or automate measurement tasks.

The advantages of industrial image processing in automation and quality assurance

Industrial image processing is indispensable in production today. Through optical detection and powerful analytics, machine vision improves quality, precision, and efficiency in production processes. With high speed and constant precision, this technology surpasses the capabilities of human inspectors.

Increased production speed

Machine vision systems enable real-time inspections and fast data collection, increasing throughput – without sacrificing quality.

Flexibility in different applications

Vision systems are versatile and can perform tasks such as component positioning, surface inspection, or measurements.

Increased quality

High-resolution cameras detect even the smallest defects, reducing scrap and rework.

Reduced labor costs

Through automation, machine vision replaces human inspectors and reduces costs while maintaining or increasing production utilization.

Improved occupational safety

In hazardous environments, camera systems take over high-risk inspections, minimize hazards, and protect employees.

Preventive maintenance

Machine vision enables preventive maintenance, avoids breakdowns, and extends the service life of machines.

Machine vision tasks

The detection and localization of objects are tasks that industrial image processing is well suited to perform. In this video, our expert Thies Moeller uses vivid examples to explain how these tasks are tackled by machine vision systems and what role image preprocessing plays in this procedure.

Industrial applications

Industrial image processing has become indispensable in a wide variety of industrial applications. By using sophisticated cameras and intelligent image processing software, it enables unrivalled precision and efficiency in production processes.

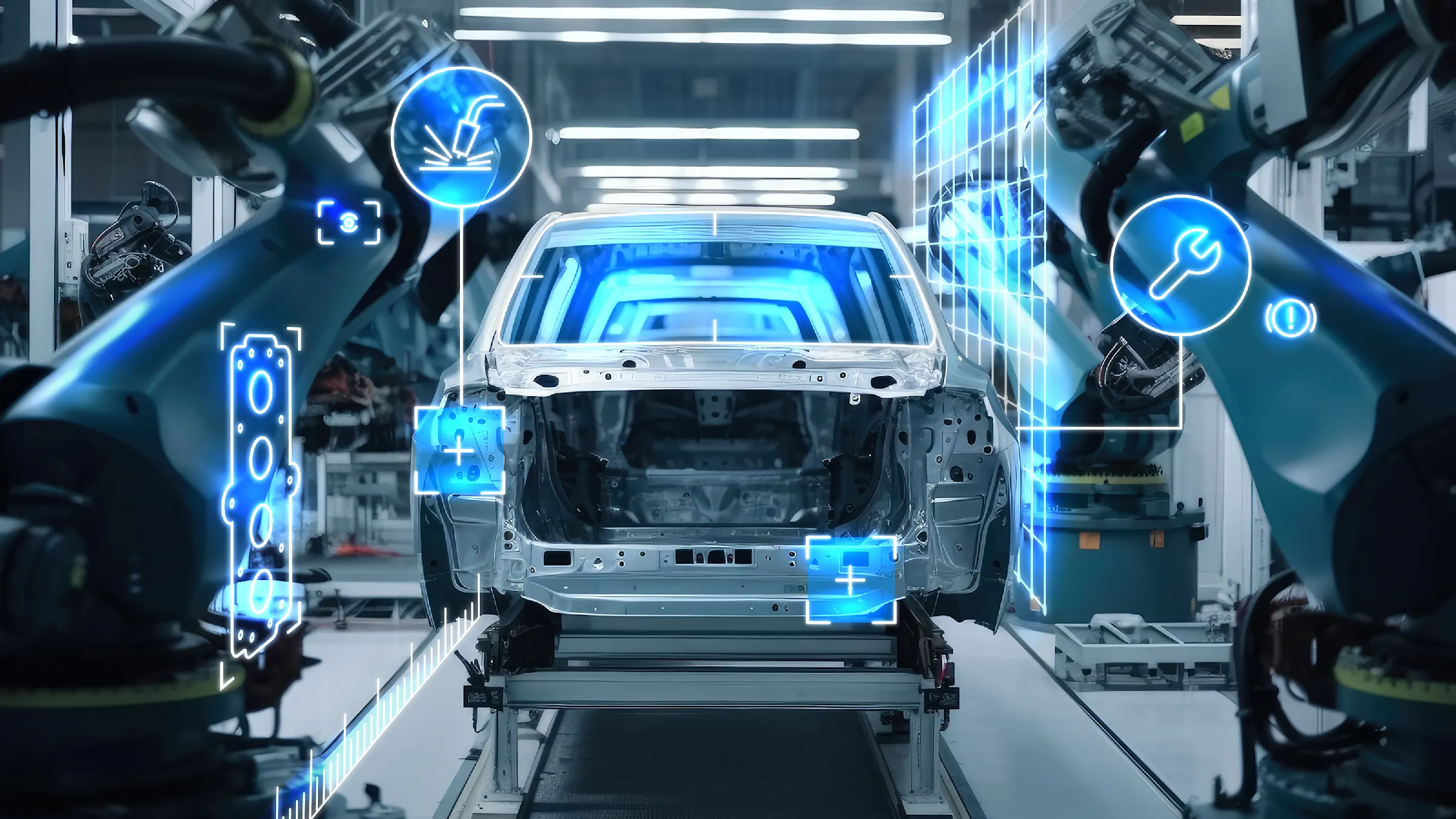

Robotics and automation

Image-guided robotics uses cameras to guide and control robots. In pick-and-place tasks, cameras identify objects, then determine their position and orientation so that robotic arms can grab them and place them correctly. This application is often found in both the automotive industry and packaging technology.

Traffic & Transport

In traffic engineering, machine vision plays an important role in license plate recognition, speed monitoring, and the inspection of rails.

Battery cell production

In battery cell manufacturing, industrial image processing helps reduce scrap and rework, saving cost and increasing production efficiency. Furthermore, the use of machine vision can improve throughput, as automated inspections are carried out in real time and do not interrupt the production flow.

Printing industry

In the printing industry , machine vision is used to monitor the printing process and detect color deviations or printing defects. High-speed cameras can monitor the printing process in real time and intervene immediately in the case of deviations.

Food industry

The optical inspection of food for foreign bodies, correct size, ripeness, or mold infestation is also an application for machine vision systems. For example, fruit can be sorted automatically or packaging can be checked for completeness and correct labelling.

Pharmaceutical industry

In the pharmaceutical industry, extremely high product quality is required to ensure the health of patients. Machine vision systems inspect tablets and capsules for the shape, color, and integrity of the marking. The correct filling quantity of liquids in ampoules or vials can also be ensured.

Agriculture

Modern agricultural machinery uses machine vision to distinguish plants from weeds and perform targeted fertilization or herbicide treatments. The evaluation of harvested material for maturity and quality or monitoring farm animals is also made possible by industrial image processing.

Machine vision for high production quality

Machine vision enables process automation, improvements in product quality, and increases efficiency. In this way, it increases the quality of production processes, reduces costs, and thus contributes to greater competitiveness.

Our products for industrial image processing

Use our Vision System Configurator to easily assemble your complete vision system.