What Is Multispectral Imaging?

Multispectral imaging reveals information that remains hidden to the human eye. But what exactly does multispectral mean? And what impact does this technology have on industrial image processing? We will show you how your vision application can benefit from multispectral cameras.

Application examples for multispectral imaging

In our webinar, we answer the most important questions about multispectral imaging:

What is multispectral technology?

What can it be used for?

Best practice examples

What are multispectral cameras?

Multispectral cameras are highly specialized industrial imaging devices that see much more than "just" color. They measure image data in specific wavelength ranges of the electromagnetic spectrum, far beyond what the human eye can see (380-780 nanometers). They typically cover 3 to 15 spectral bands, but there are also cameras that can capture hundreds of spectral bands, known as hyperspectral imaging.

These cameras open up new possibilities by visualizing electromagnetic waves with wavelengths outside the visible range, such as infrared. This precise capture of spectral information is helping to improve efficiency and quality assurance in a variety of industries.

These cameras open up completely new possibilities by visualizing electromagnetic waves with wavelengths outside the visible range, such as infrared. This precise capture of spectral information contributes significantly to increased efficiency and quality assurance in various industries.

Options for spectral imaging

There are three ways to obtain spectral image information: a camera with optical elements, a continuous filter such as a filter wheel, or a CMOS sensor with a filter.

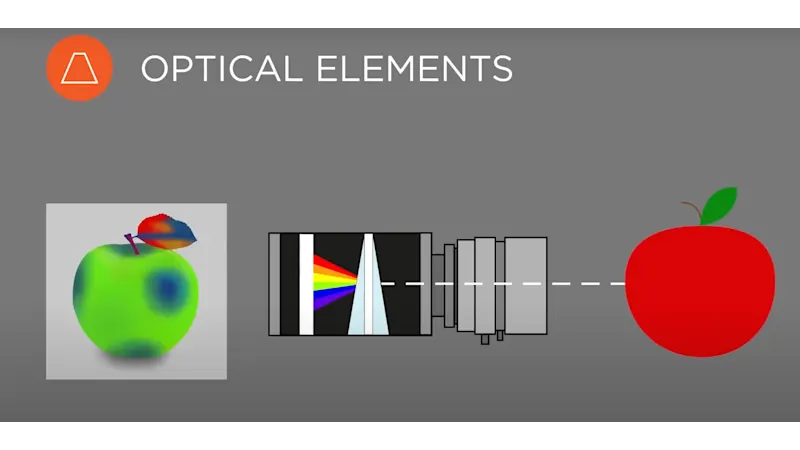

Multispectral cameras with optical elements

Multispectral cameras with optical elements consist of four main components:

Prism:

Splits the incident light into different wavelengths.

Sensor:

Converts the light into electronic signals.

Grating:

Isolates specific wavebands.

Lenses:

Focus the light for further processing.

Together, these components generate a high-resolution multispectral image. Performance is highly dependent on the precise alignment and calibration of the optical elements, which can be costly.

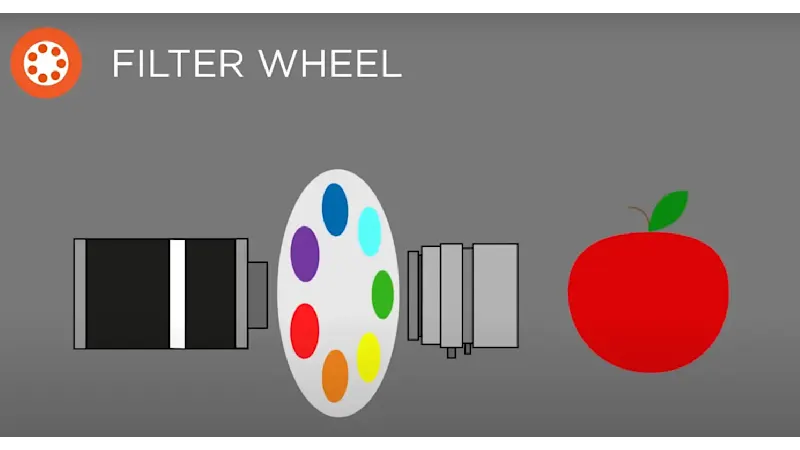

Filter wheel cameras

Objects captured with filter wheel cameras are scanned sequentially as the camera captures single wavelengths. For additional wavelengths, the filter wheel must be moved to the desired filter. However, this method has its limitations, especially with moving targets. The slower scanning speed can result in blurred or incomplete images.

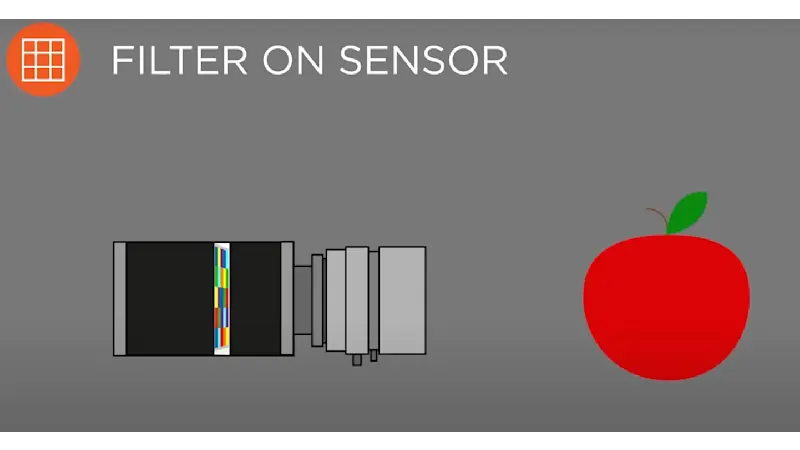

CMOS sensor with filter

CMOS sensors are now available with bandpass filters integrated into the sensor layout. Unlike other scanning techniques, cameras with spectral filters on CMOS sensors do not require additional optical components to be aligned. They capture objects of different wavelengths in a single image. These sensors are not only less expensive, but also easier to integrate into existing imaging systems.

Overview of multispectral camera applications

Multispectral cameras have evolved in recent years from their original use in aerospace, life sciences and laboratories and are now widely used in other areas, e.g:

Printed circuit boards: Inspection to detect faults and defects

Banking: Counterfeit detection of banknotes

Dermatology: characterization of skin changes and diagnosis of skin diseases.

Focus on multispectral imaging: food industry & agriculture

The main application for multispectral cameras is in the food industry and agriculture.

Agriculture

In agriculture, farmers can assess the condition of their crops. Drones equipped with multispectral cameras fly over the field and capture high-resolution images that are transmitted wirelessly to a computer on the ground. By evaluating the data in different colors, such as red and green, farmers can identify diseased plants and treat them with targeted pesticides. This enables the efficient use of resources and protects the environment.

Food production

Multispectral imaging also plays an important role in food production and enables even more precise quality control. Automated processes such as food sorting benefit from the precise detection of foreign objects. While conventional industrial cameras have difficulty distinguishing between debris, stones and dirt, multispectral cameras are able to detect even the smallest deviations.

The future of multispectral imaging

As technology advances and multispectral cameras become more integrated, we can expect even more accurate and reliable analysis in the future, continuously optimizing industrial processes.