Innovative Laboratory Automation for More Reliable Cancer Diagnoses

- Customer

- inveox GmbH

- Location

- Garching, Germany

- Date

- 2019

In Germany alone, hundreds of patients are misdiagnosed or incorrectly treated every year due to flawed or misplaced laboratory findings. The Garching-based company inveox has developed an innovative solution for the digitization and automation of pathology laboratories that addresses this problem. Image processing from Basler plays a key role in this system.

Errors in manual procedures are the most common reason for incorrect cancer diagnoses. Experts estimate that irregularities occur in around 1 to 15 percent of cases and, in the worst case, can lead to misdiagnosis and incorrect treatment, with potentially fatal health consequences for patients.

What are the problems with laboratory diagnostics?

Statistically, every second person is confronted with a cancer diagnosis at least once in their lifetime. In addition to other diagnostic procedures, this is usually based on the analysis of a tissue sample taken from the body. "While medicine is making great technological advances almost daily, many processes in pre-analysis have remained unchanged for decades, which makes them increasingly problematic," says Dominik Sievert, founder and CEO of inveox. The initial data entry for the sample, in particular, is considered the "Achilles heel of histopathology" by experts. As a (usually) manual procedure, it is a prime candidate for optimization. "The procedure here is almost the same worldwide: time-consuming, expensive, and error-prone." In addition, irregularities, such as mix-ups, contamination, or even the loss of tissue samples (which can occur as soon as the sample is received) are a serious problem in the current process.

This scenario was the impetus for inveox founders Dominik and Maria Sievert to think about possible optimizations of processes from sample collection to laboratory analysis and beyond. The developments that inveox has since brought to market maturity can be described without exaggeration as a revolution in laboratory automation.

Three innovations for more safety in laboratory automation

"Our goal was to enable fast and reliable cancer diagnoses through digitized, fully automated, and networked histopathology - from sample collection to microscope slide," explains Dominik Sievert. To this end, inveox has developed a laboratory automation system that comprises three key components: an intelligent sample container for tissue biopsies, an automated device for the sample entry, and a highly secure online platform for structured communication and data transfer between the attending physician and the pathology lab.

A single sample container for the entire pre-analysis

The intelligent sample container makes it possible to carry out several crucial pre-analysis steps with a single container. "In today's standard processes, the tissue taken from the patient for examination is manually repackaged several times into different containers and relabeled each time, which naturally involves a high susceptibility to errors," says Dominik Sievert. The inveox biopsy cassette contains an integrated filter that allows the formalin in which the tissue is stored to be disposed of before further processing without having to remove the sample from the container. As the sample always remains in the same container with a unique ID, mix-ups and contaminations are eliminated.

Automation device for sample collection and seamless additional processing

These new sample containers were the starting point for the second innovation: a special automated system for receiving samples, also developed by inveox, in which several dozen sample containers can be inserted simultaneously and processed automatically. The sample data is captured fully automatically, the formalin is removed, and images of the tissue are taken for documentation and additional findings. The sample, which is still in the original, coded biopsy cassette, is then dispensed from the automated device for seamless additional processing and examination in the lab.

Online platform for structured communication and reliable diagnoses

"The majority of communication regarding tissue examinations between the laboratory and doctor is still done on paper," says inveox Managing Director Maria Sievert. Thanks to a web-based, encrypted data and communication platform, the diagnosis-relevant data obtained during the tissue examination (such as images and descriptions) are collected in a highly secure IT database and made available to the pathologists in their existing laboratory information systems. In this way, the attending physician and the laboratory benefit from secure, structured, digital communication and data transfer in real time, as well as a faster, more reliable diagnosis." Both can obtain structured information about the current status of the sample at any time - from collection and digital examination order to the diagnosis.

Automation components can be used individually or together

These three components of our automation system can be used independently of each other and each solves a core problem. However, when used in their entirety, they have the greatest effect and lead to increased patient safety and an increase in efficiency of 50 to 70 percent during the sample collection. For medium-sized pathology laboratories, this could mean the equivalent of up to 200,000 euros in potential savings per year, and even more for larger institutes such as university hospitals.

Image processing as a core element of the automation system

As an integral part of the automated equipment and thus of the entire inveox lab automation system, image processing forms the basis for many of the system's advantages. The tissue samples pass through several steps fully automatically in the sample entry devices, such as touchless formalin removal, automated repackaging of the tissue from the transport container into the biopsy cassette, and laser labeling of the biopsy cassettes. Basler dart cameras integrated into the automation device take multiple images of the tissue samples in the sealed containers, which are made of a crystal-clear material for this purpose. At the same time, they also capture their barcode. To this end, the containers are aligned fully automatically in the automation device and rotated into the optimum position for image capture.

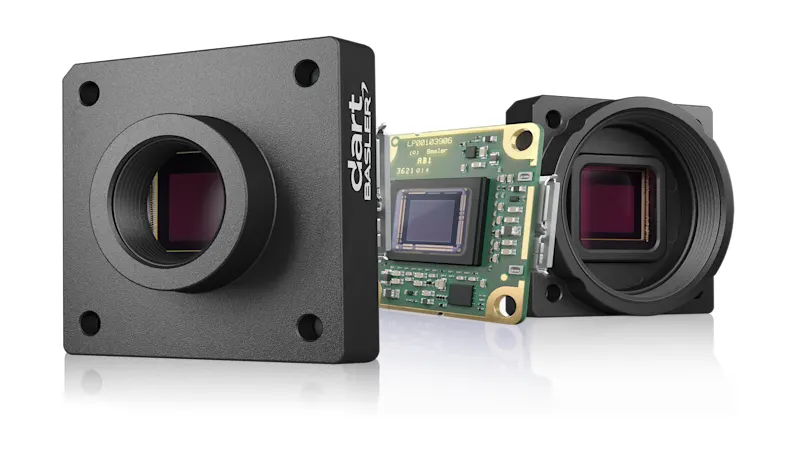

dart cameras as the vision basis for the automation solution

Depending on the configuration, up to five board level cameras from the Basler dart series are currently used in the automatic samplers, which provide more than sufficient resolution and speed for this application.

AI and machine learning support image interpretation

The captured images are interpreted using software developed by inveox, which uses artificial intelligence and machine learning to automatically derive recommendations for action and decisions based on the images. For example, an immediate assessment is made as to whether or not a sample is suitable for the subsequent steps based on its size, and unsuitable biopsies are rejected.

The results are comprehensive 360-degree images of the samples as well as several parameters such as dimensions, shape, color, and texture. These fulfill another important function in addition to documentation purposes: Pathologists can later call them up in the database for further diagnoses, view them again in digital form, and possibly draw conclusions from the original condition of the sample. "Until now, it was generally not possible to draw conclusions from the original tissue samples," explains Sievert.

We purchase all our image processing components from Basler. Their wide selection of cameras was a key argument for us to work together. However, at least as important as the availability of the optimum vision components was the fact that Basler treated us as equals from the outset and had confidence in our idea. The fact that we were treated as an equal partner, even though we were still in the start-up phase, made a big impression on us.

We value Basler as a cooperative and reliable business partner that responds quickly to our inquiries and provides us with professional support in every respect - from the spontaneous loan of camera models for comparison to integration support. Considering our long-term expansion plans in other countries, we do not have to look for new suppliers locally, but can rely on an already proven partner.

Products for this solution

Looking to implement a comparable solution? These products will help you.