SWIR Vision Systems in Agricultural Production

Improved produce inspection through short-wave infrared light

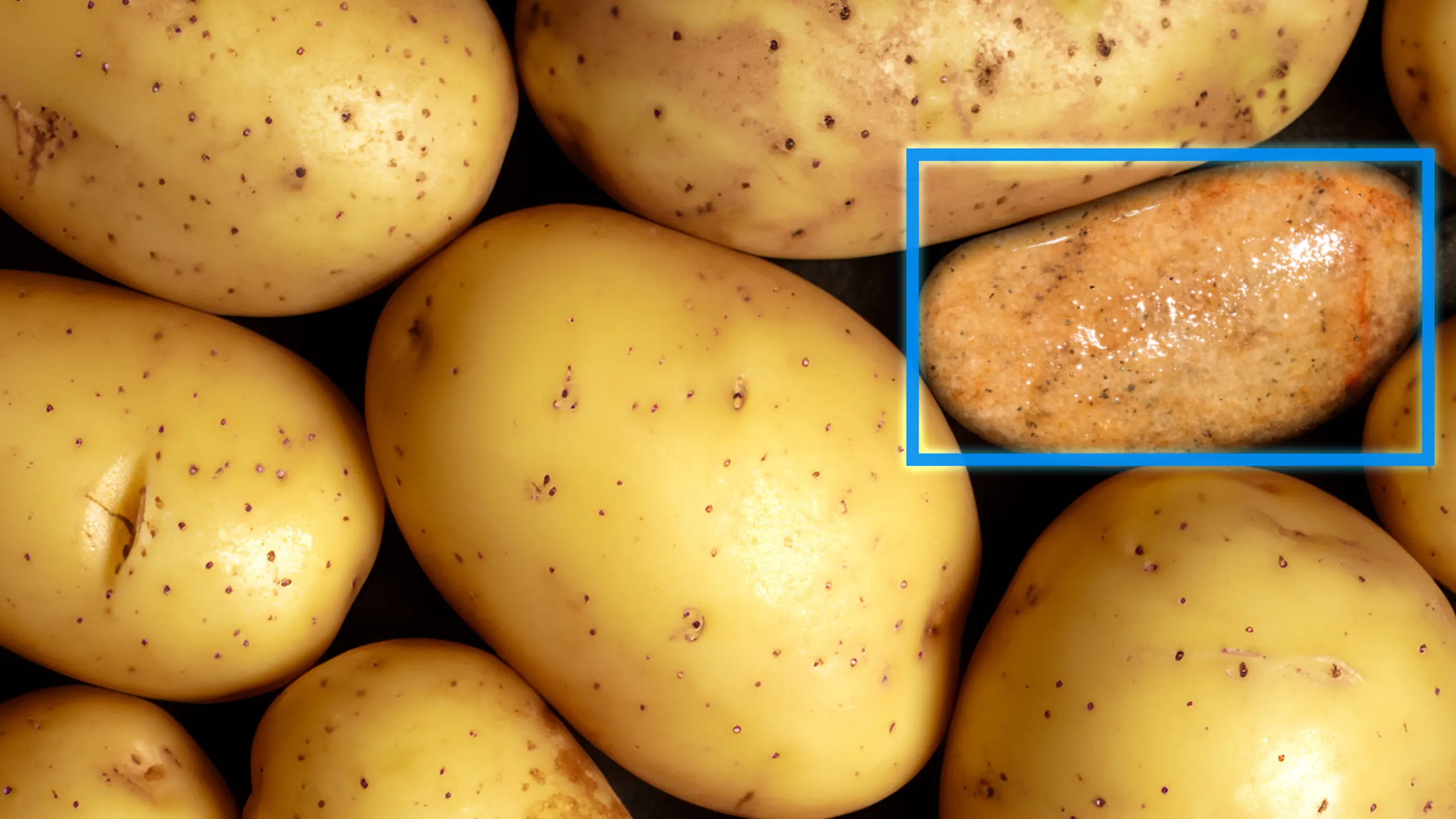

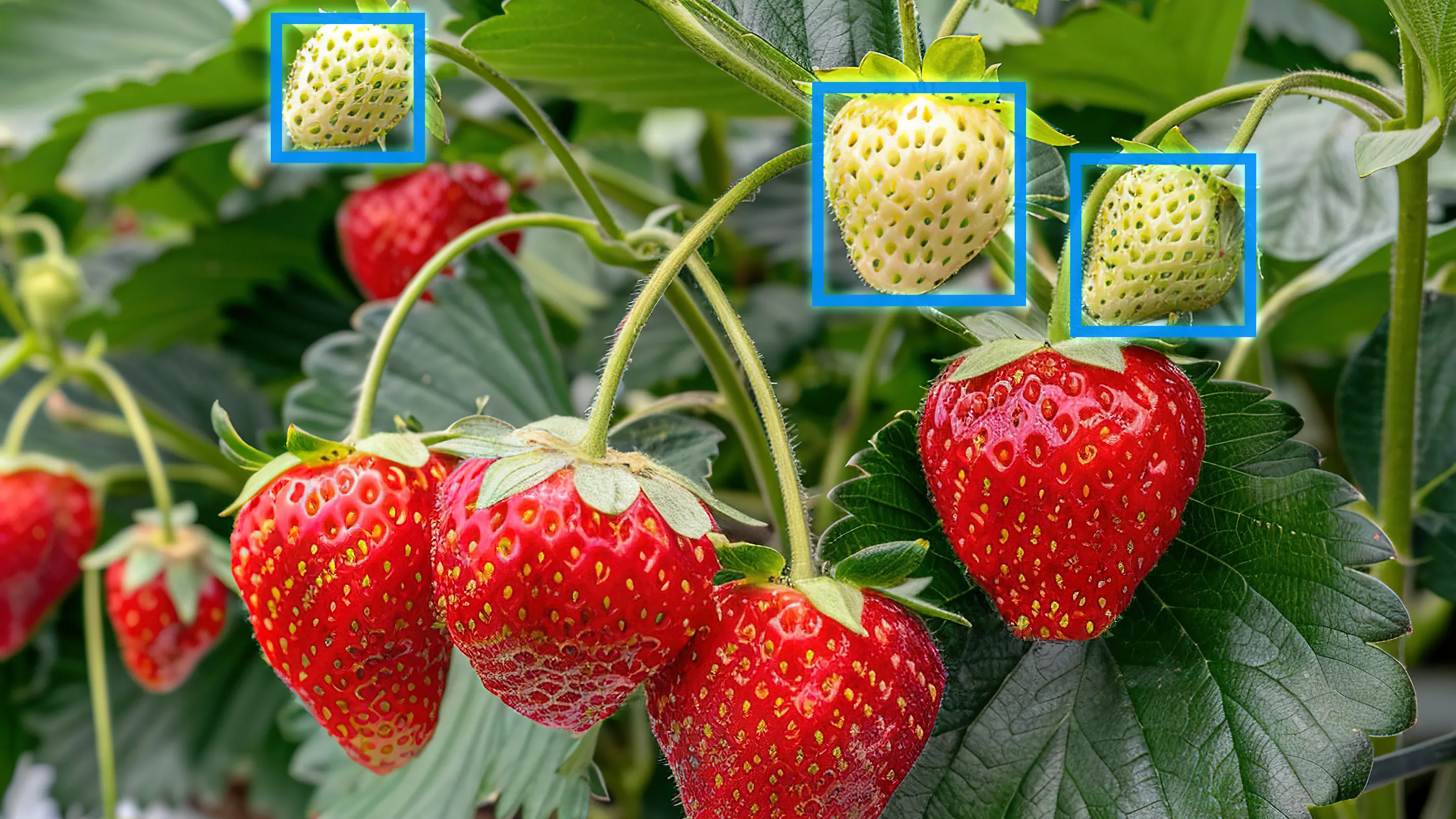

Ensuring the quality of fruits and vegetables such as apples or potatoes is crucial to meet market standards and consumer expectations. Traditional inspection methods are often based only on visual observation, which is time-consuming and error-prone. SWIR vision systems from Basler offer a reliable vision solution for quality control in food inspection.

SWIR applications for agricultural produce

SWIR vision systems offer a wide range of applications for more efficient and reliable inspection of agricultural products, e.g. in the event of damage or contamination.

See what is hidden beneath the surface

The properties of short-wave infrared light (SWIR) offer exciting possibilities and new methods in quality assurance.

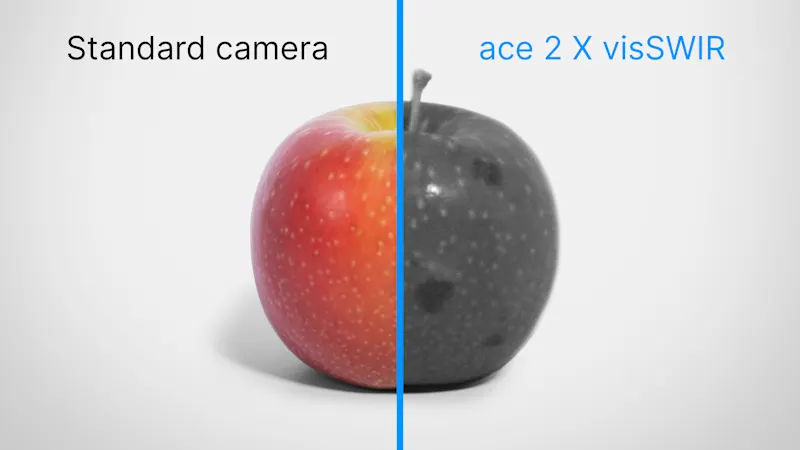

visSWIR provides additional information

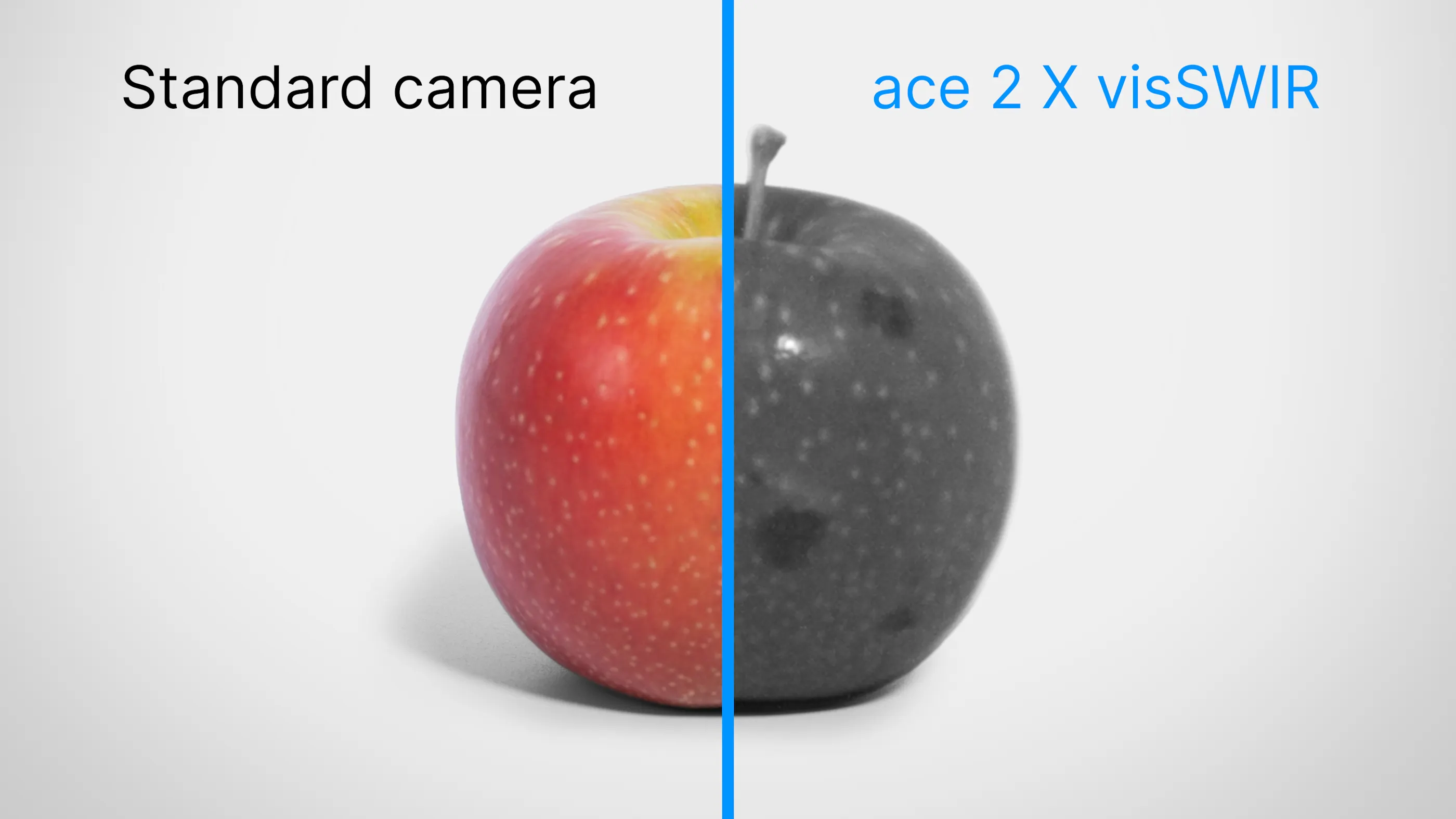

The example of apples damaged by bruises clearly shows the limitations of traditional inspection methods: they are mostly based on mere visual observation, which costs a lot of time, is subjective and prone to human error. Attempts to overcome these limitations by imaging in the visible spectral range are ultimately unable to deliver the required level of detail: what is needed is a vision system that can see below the surface.

SWIR: Systematic visibility

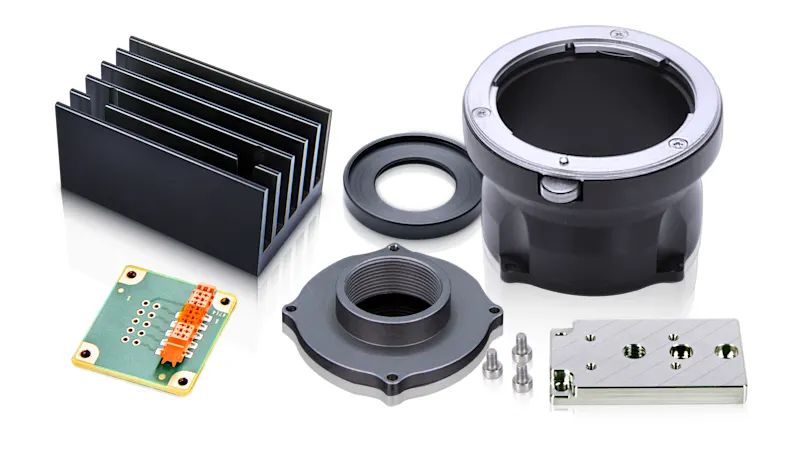

For image acquisition in the SWIR range, special products are required that are adapted to the short-wave infrared spectrum. Because the SWIR technology works as a system: Selecting the right lenses, filters, and light is critical to the quality of SWIR imaging and requires an understanding of the specific requirements of each application.

Components of the SWIR vision system

The Basler ace 2 X visSWIR camera allows for the detection of both visible and invisible light, enhancing the effectiveness of inspection processes. In this example, near-infrared (NIR) and short-wave infrared (SWIR) light penetrate the apple peel, revealing variations in moisture resistance, particularly in areas with higher water content. However, a successful SWIR vision system involves more than just this capability:

Traditional lenses are typically optimized for the visible spectrum. However, pure SWIR lenses can exclude the visible range. To capture both, Basler offers custom lenses designed for this purpose. visSWIR-compatible lenses.

Optical filters are crucial in SWIR applications because they can control light transmission depending on wavelength ranges.

SWIR illumination with LEDs ensure reliably high, consistent image quality in SWIR vision systems.

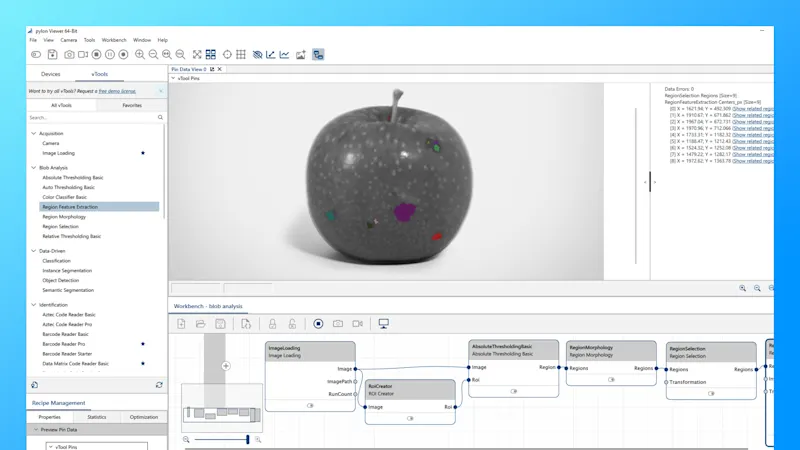

Using blob analysis for localization

The software is what makes the application intelligent. In addition to the vision hardware, the Basler Blob Analysis software module is used to segment and analyze the dark areas. Blob analysis detects distinct regions within an image based on their grayscale values. This allows for the identification of defects, impurities, or variations in sugar content, enabling appropriate actions to be taken. As a result, product inspection efficiency is significantly improved.

Do you need support for your specific application? We would be happy to share our SWIR portfolio tailored to your application in an individual consultation.

Automatic correction of pixel defects

The Basler ace 2 X visSWIR models feature SenSWIR sensors from Sony, based on InGaAs technology. These sensors are characterized by smaller pixels, offering higher resolutions than conventional sensors. To address the pixel errors commonly found in industrial SWIR imaging, we developed Pixel Correction Beyond.

Pixel Correction Beyond: Images without pixel defects

The pixel defects typical of InGaAs sensors can have a negative impact on image processing. Pixel Correction Beyond is a dynamic defect pixel correction and one of the reasons for the outstanding image quality of our SWIR cameras.

This feature is powered by an algorithm developed by Basler. During operation, it detects pixel defects in each image and automatically corrects them within the camera's FPGA, without distorting the image content.

SWIR: Perfect for agricultural produce inspection

Basler's SWIR vision systems enhance the efficiency and reliability of produce inspection in the agricultural industry. These camera systems assist agricultural producers with quality assurance, defect detection, and sorting efficiency, leading to improved workflows, compliance with market standards, and the delivery of consistently high-quality products to consumers.

Advantages at a glance

Vision system with coordinated components for improved image clarity and accurate defect detection

Reliable defect detection with advanced vision algorithms to accurately identify defects and reduce the risk of oversight

Optimized sorting process based on real-time analytics for improved overall operational efficiency

Products for this solution

Looking to implement a comparable solution? These products will help you.