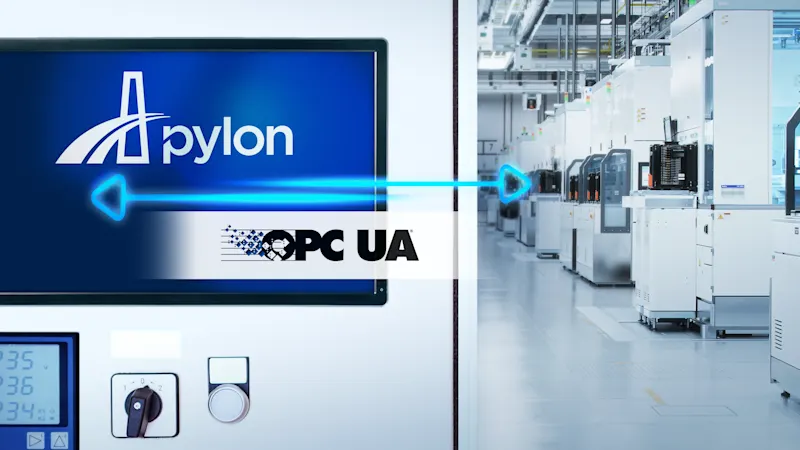

OPC UA – Uniform Protocol for Machine Communication

OPC UA is the standard for seamless, platform- and manufacturer-independent machine communication in industry 4.0 and IIoT. In addition to secure data exchange, OPC UA enables easy integration and machine-readable semantics.

System components speak the same language with OPC UA

In networked industry 4.0 and IIoT, smooth machine communication is essential. OPC UA enables the secure, platform- and manufacturer-independent exchange of data and information – far beyond pure transport. Thanks to standardized, machine-readable semantics, integration becomes easier and more efficient.

OPC UA also offers seamless plug-and-play integration of vision systems in industrial image processing. This allows cameras to be flexibly controlled and image analyses to be automated – without any programming effort or adaptation to manufacturer-specific specifications. The ideal solution for future-proof, digital production.

OPC UA and machine vision – important questions and answers

OPC UA has established itself as the standard for efficiently networking machines and image processing systems. But what makes OPC UA so important, and what advantages does it offer specifically for machine vision? We answer key questions on this topic.

Why has OPC UA gained importance in recent years?

In industry 4.0, state-of-the-art technologies are expected to lead to significant increases in efficiency. To ensure that the complex technology in production remains easy to control, both standards and safety in the interaction of all system components are important. OPC UA offers both: simple and secure machine-to-machine protocols regulate communication and make the advantages of industry 4.0 usable. Many technical hurdles have been overcome in recent years, creating the basis for growing acceptance.

What is the OPC UA Companion Specification for machine vision?

OPC UA provides the basic communication. However, the details of a machine vision device require additional specifications that take into account the specifics of image processing. The OPC UA Companion Specification for machine vision defines the operation, control, and internal structure of an image processing device. It is divided into several parts. Part 1 was completed in 2019. Part 2 is currently being worked on.

What are the benefits for users of the OPC machine vision specification?

The OPC machine vision interface allows plug-and-play integration of machine vision systems into complex environments. This saves users effort for the development and integration of "homemade" solutions and can rely on proven and stable implementations in the company. OPC machine vision allows the use of existing interfaces and vertical and horizontal integration in the automation pyramid all the way to the cloud.

Our OPC UA connection

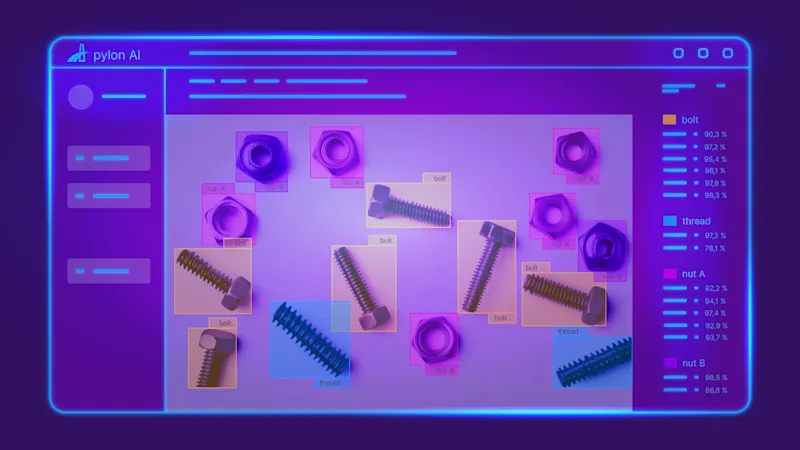

Discover the simple solution: a pylon vTool for easy OPC UA interface connection. pylon vTools are flexible add-ons for your image processing in the pylon Software Suite.

OPC UA vTool

With the OPC UA Client vTool, you can send the results of your vision pipeline to an OPC UA server to ensure smooth and efficient data exchange. The simple plug-and-play integration saves you the hassle of coding.

To the OPC UA vToolAdditional information

Learn more about the role of vision systems in industry 4.0 and the importance of OPC UA for seamless machine communication. Our additional content provides you with all the important details.

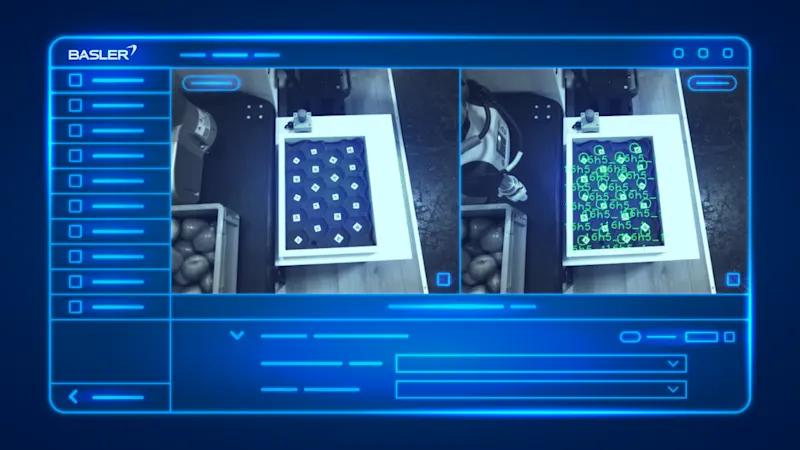

Vision systems as data suppliers

Among the most important and powerful sensors in an automated factory environment are vision systems with cameras. They usually consist of the following components: